產品列表

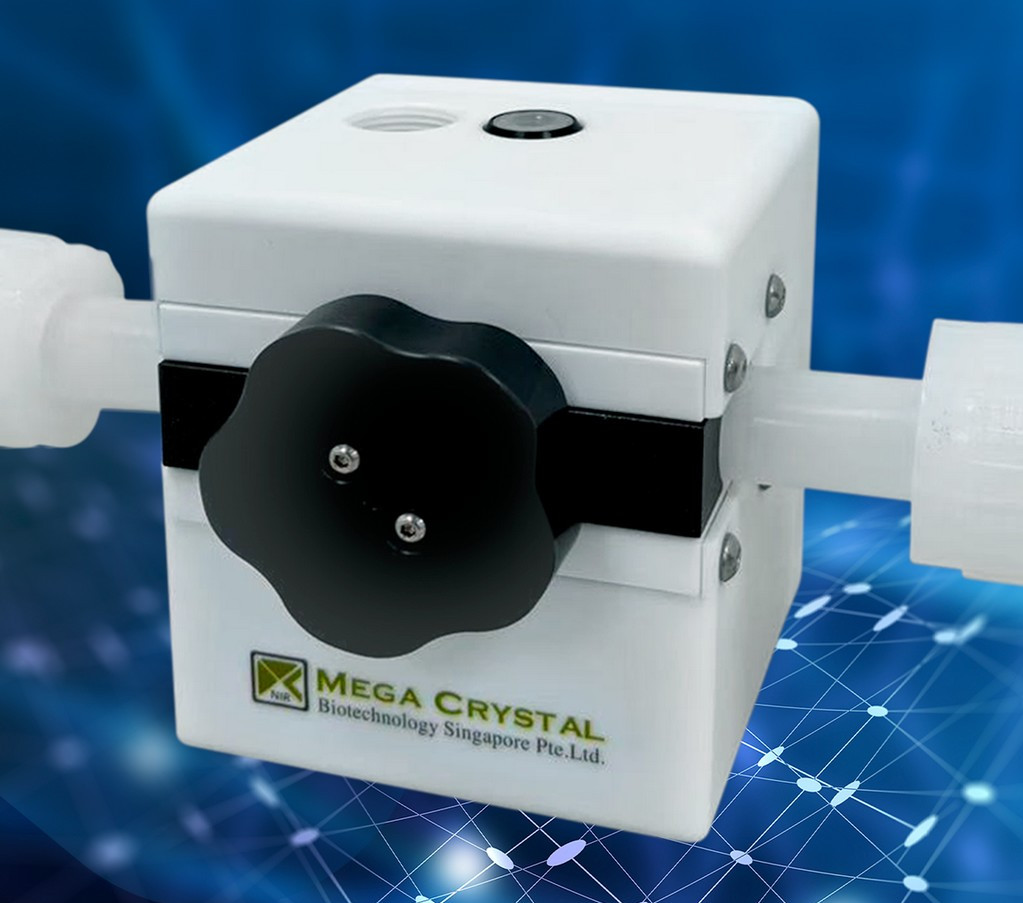

即時液體濃度分析儀

兆晶專注於光譜材料分析技術,提供高效能的光學式即時液體成分分析設備,幫助客戶精準監控化學槽內酸、鹼及有機成分比例,提升製程穩定性並有效節省藥水。

產品特色

• 快速檢測:無需耗材,最快10秒產出分析數據

• 多樣分析:適用於混合藥液檢測,可同時分析6~8種成份

• 準確性高:可監測微量添加劑、金屬離子(Au,Cu,Pd,Si,Ni...等)至100ppm以下

• 使用彈性大:濃度範圍寬廣,無需因濃度變化變更硬體

• 非接觸式檢測:不接觸藥液,避免污染與損耗

• 即時連線:支持多種數據傳輸方式,實現檢測結果即時上傳

• 耐高溫能力:可檢測高達 160°C 的藥液

適用範疇

• 半導體製程:SC-1、SC-2、SPM、DHF... 等

• PCB 製程:銅/鈦蝕刻、電鍍、化學鍍、顯影...等

• 各類濕製程及創新藥液應用

兆晶致力於為產業提供更智慧、更可靠的液體分析解決方案,協助您在激烈市場中保持競爭優勢。